Global demand for better fuel economy, low engine emissions, and better vehicle response speed require engines with better combustion systems. A common rail diesel engine using direct fuel injection technology led to a significant improvement in emissions, fuel consumption and power density. A key constituent of such system is a Piezoelectric fuel injectors consisting of a multi-layer piezoelectric stack actuator acting on a nozzle with a speed 4~5 times faster than the older solenoid counterpart. In this project, a direct mechanical acting piezoelectric fuel injection technology is being developed based on a novel large stroke compact multi-stack piezoelectric actuator with the injection nozzle needle directly connected to the actuator and without any amplification mechanisms. The new actuator when developed will also feature self-sensing capability and temperature compensation in order to enhance the control of the fueling process. This improved combustion control will lead to a further reduction in emissions, higher torque and improved fuel economy.

The fuel injector program at MMDL started in November 2009. MMDL is part of a large consortium of Universities and Industries that are working together on this project.

Objectives of Program

- Develop a novel compact piezo actuator suitable for integration into injectors. The actuator needs to provide a stroke of 300 μm and provide a sufficiently high stiffness while operating under high engine pressures and a fast response time.

- Develop a self-sensing mechanism and control algorithm to realize closed-loop control of the injection motion.

- Development of efficient electric driving modules for piezoceramic actuators especially designed for the automotive environment and develop temperature compensation algorithms for the piezoceramic stacks while operating in the engine.

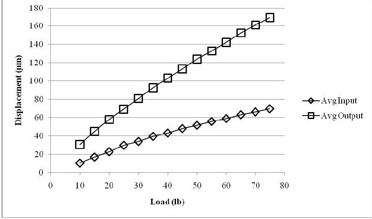

Fig. 1. Displacement vs load for the prototype actuator tested (courtesy of Prof. He).